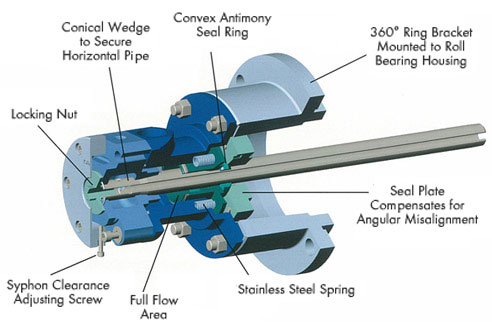

CorrPro™ Rotary Joint (US Patent No. 6,203,072 )

The CorrPro rotary joint from Kadant Johnson was the first to include an externally adjustable syphon clearance that is adjustable from outside the roll. The patented design allows the operator to adjust the clearance between the internal roll surface and the syphon vertical pipe after the joint and syphon equipment is installed.

The CorrPro rotary joint uses balanced seal technology that outperforms any rotary joint on the market today. Operating torque is reduced by nearly 60% compared to conventional steam joints, resulting in lower energy consumption and less seal wear. The bracket-mounted design provides for a rigid support and eliminates side loading from flexible hoses.

The advanced CorrPro system is guaranteed to perform without maintenance from roll grind to roll grind when installed by Kadant Johnson. With these and other features, the CorrPro joint has become the preferred steam joint of wet end corrugating OEMs worldwide. The CorrPro steam joint is rated up to 450° F (243° C), 300 psig (20 bar), and 600 RPM.

Features

- Balanced seal design with AI technology

- Circular bracket mounting

- Seal wear indicator

- Adjustable syphon clearance

Benefits

- Minimized seal loading and seal wear

- Rigid support for safety and reliability

- On-machine measurement of seal wear

- Optimize heat transfer and temperature uniformity

Specifications

| Max. Pressure | Max. Temperature | Max. Speed |

|---|---|---|

| 2.0MPa | 232°C | 600rpm |

Head installed rotary syphon

Head installed rotary syphon Head installed stationary syphon

Head installed stationary syphon| Type | Syphon | Size(K) | M | P | S | A | B | C | D | E | G | J |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9500CASC-PT | Stationary Syphon | 1 - 1/2" | 1 - 1/4" | 3/4" | 3/4" | 48 | 76 | 241 | 137 | 76 | 54 | 244 |

| 9500CASC-PT | Rotary Syphon | 1 - 1/2" | 1 - 1/4" | 3/4" | 3/4",1" | 48 | 76 | 241 | 138 | 76 | 56 | 213 |